This hand cranked paper shredder is really satisfying. It’s on a cool double-drawerslide disappearing bracket. It sounds like loading a machinegun when you pull it out. Once someone starts shredding you can’t stop them til the scrap paper is all gone.

Much skillful photography, craftsmanship, video editing, etc by Fungusamungus

Step 1: Plot summary up to this point…

“Bicycle powered shredder” thought I. First I would try it by hand just to get a feel for it.

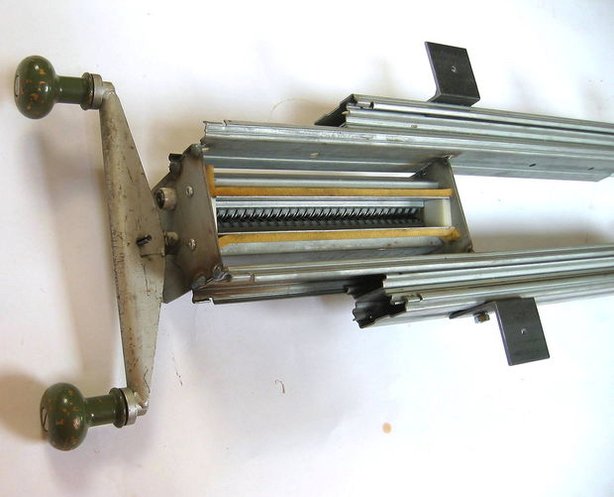

I had a crank handle from an astronaut-torturing machine that happened to fit over the shredder’s drive shaft.

There was a hole for a retaining pin in the driveshaft. I drilled the crank to match, pounded in the pin, and Voila! Hand-cranked shredder.

Then I clamped it to a table and everyone started shredding documents until we couldn’t find any more paper.

It all happened so fast I didn’t take pictures of the steps, but your junk shredder and your crank will most likely

be totally different. Try a handle from an old meat grinder or a crank from a bicycle.

Hand shredding is so satisfying and convenient I don’t know if I’ll make the pedal grinder.

If you do it let me know how it turns out. Next came the process of fitting it under a table in just the perfect way. Continue…

Step 2: Saw off the Extra Stuff

My granddad used to say: To carve a wooden bear take a piece of wood and cut off everything that doesn’t look like part of a bear.

Step 3: Two Double Drawerslides

Step 4: Setting up the Assembly

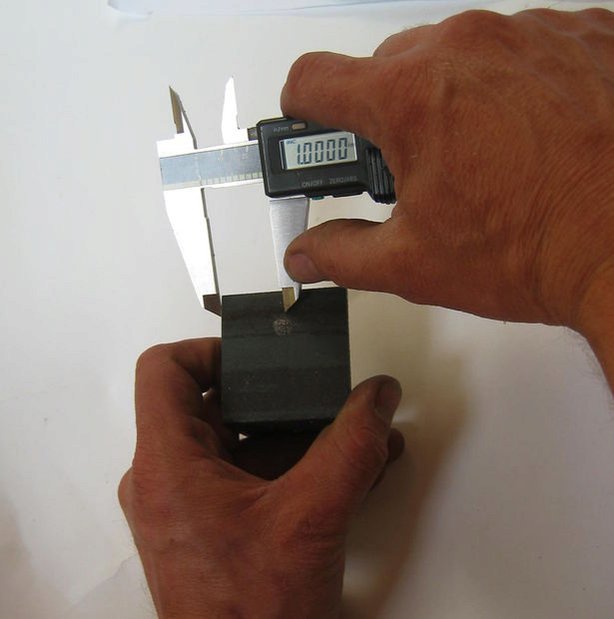

The slides needed to be level and parallel. Fungus mikes out our tolerances.

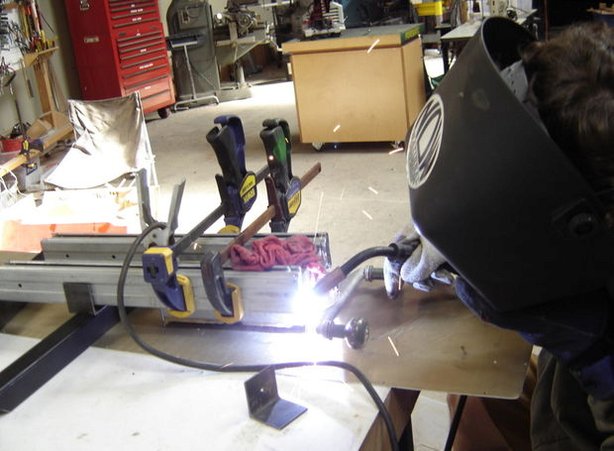

Step 5: Weld it Together

I draped a soggy wet rag over the metal between the weld and the plastic bearings. Then after welding I mopped at the hissing welds to chill them as soon as I could without cracking them.I used the shop’s wirefeed welder. To make welding easy, use Miller’s online welding calculator to find out what amperage, gas pressure, wire feed rate, etc. for the material and type of weld you’re doing.

Step 6: Bracketizing Step One: Rough Marking

They needed additional holes. Here’s how “shop guy” does that. Setup your assembly with clamps or by hand and mark where the mating hole will go.

Step 7: Bracketizing: Cross Scribing with Caliper

Scratch two lines that cross where you want your hole.

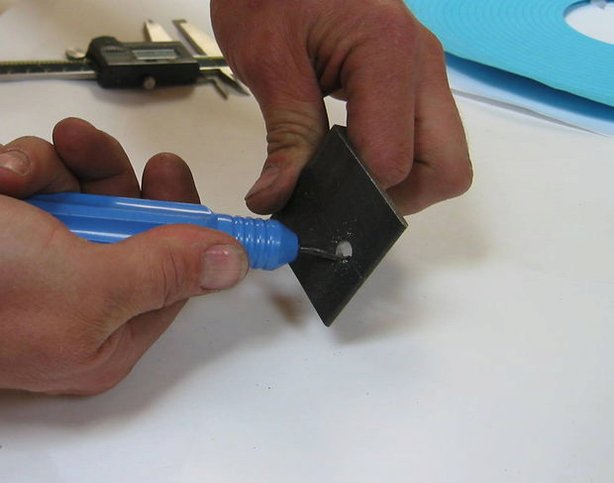

Step 8: Finding the Center

Take your center punch and run it along one of the scratches until the tip drops into the deep spot where the two grooves cross.

Get an old Industrial Arts textbook. It’ll have these tricks and more.

Step 9: Center Punching

Your eyes will be pretty accurate. If you don’t like where it is you can push it around by centerpunching at it from an angle.

Step 10: Lube Your Bit With a Candle

Step 11: Drill the Hole

Consult your industrial arts textbook for proper info on drill sharpening, tool speed, and feed rate. It varies with the material. It’s interesting how a drill, saw blade, and lathe bit have similar cutting parameters.

Small pieces must be clamped or the drill will bind, spin them, and mess up your hands.

Step 12: Deburring Tool

Step 13: Houston, we have Brackets

Step 14: Standoffs

Step 15: Pattern and Mounting Holes

Step 16: Bolting it On

Step 17: In Action

Step 18: The Shred Bed

How about using the shreds to make your own improvised futon?

For initial tests we used giant drawstring bags. For comparison we filled one bag with crumbled newspapers to make a “crumple bed”. Marion tests them out. Conclusions: It takes a huge quantity of stuffing to make a futon. The crumblebed is lumpy, not as good as the shred bed. The shred bed is very comfortable. Marion had just finished one of her final exams and took a nap right there.